How Does Pressure Drop Occur in an Orifice Plate Flow Meter System?

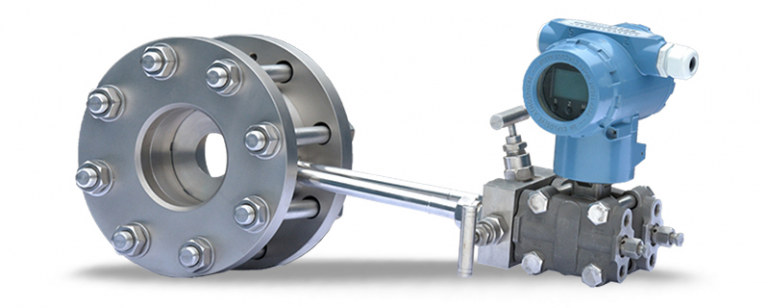

An orifice plate flow meter is one of the most widely used devices for measuring fluid flow in pipelines. Its design is simple, consisting of a flat plate with a hole at the center. When fluid passes through the hole, the flow characteristics change, creating a measurable pressure difference. This principle makes the orifice plate a practical tool for engineers.

However, the same principle that makes the device effective also leads to a loss in energy. This energy loss is observed as a pressure drop across the meter. Pressure drop is an unavoidable consequence of restricting the flow. Understanding how this occurs is vital for designing systems that use orifice plates. It ensures that accuracy is balanced with efficiency.

The following sections explain how pressure drop forms in an orifice plate flow meter system. The explanation considers the fluid dynamics at the plate, the recovery of pressure downstream, and the permanent loss that remains in the system.

Fundamentals of Flow in an Orifice Plate

The Role of the Restriction

The orifice plate flow meter works by narrowing the cross-sectional area available to the fluid. As the flow enters the orifice, it is forced through the small hole. This restriction increases the velocity of the fluid at the point of passage. According to Bernoulli’s principle, an increase in velocity causes a reduction in static pressure. The pressure difference between the upstream section and the throat of the orifice is then used to calculate flow rate.

This restriction is central to the device’s function. Without it, there would be no measurable pressure differential. Yet the restriction also introduces turbulence and energy loss. These losses are the root cause of permanent pressure drop in the system.

Vena Contracta and Flow Contraction

When fluid passes through the orifice, the jet of flow contracts downstream of the plate. This contracted section is called the vena contracta. At the vena contracta, the velocity is highest, and the pressure is lowest. The difference in pressure between the pipe wall upstream and the vena contracta is the differential pressure used to calculate flow.

After this point, the fluid begins to expand again and recover some of its lost pressure. However, because of turbulence and eddies generated at the edges of the orifice, not all the pressure is recovered. This incomplete recovery explains why pressure drop remains even far downstream of the plate.

Mechanism of Pressure Drop

Static Pressure Decrease at the Orifice

As the fluid approaches the orifice plate, the flow path narrows. Static pressure decreases as velocity rises. This conversion of pressure energy into kinetic energy is reversible in theory. If the flow could expand smoothly without turbulence, the downstream pressure would return to nearly the same level as upstream.

But in practice, energy is lost due to the sharp edges of the orifice and the sudden contraction of flow. These conditions create vortices and chaotic eddies. The energy that goes into this turbulence is dissipated as heat and cannot be converted back into useful pressure.

Pressure Recovery Downstream

After passing through the vena contracta, the jet of fluid begins to expand and reattach to the pipe walls. This process leads to partial pressure recovery. The extent of this recovery depends on the geometry of the orifice and the Reynolds number of the flow. Despite this recovery, the pressure never returns to its original upstream value. A permanent drop remains, representing energy lost from the system.

Permanent Pressure Loss

The permanent pressure loss is the key characteristic of the orifice plate flow meter system. This loss can be significant compared to other types of flow meters. The sharp-edged restriction causes more turbulence than streamlined devices such as venturi meters. As a result, the orifice plate flow meter is accurate and simple but also less energy-efficient. Engineers must account for this trade-off when designing systems.

Factors Affecting Pressure Drop

Orifice Geometry

The size of the orifice opening strongly influences pressure drop. A smaller opening creates a larger velocity increase and a greater pressure difference. This also leads to higher energy losses. Conversely, a larger opening reduces the pressure drop but also decreases measurement sensitivity.

The edge design of the orifice plate also matters. A sharp-edged orifice creates more turbulence, while rounded or beveled edges may slightly reduce losses. However, the standard orifice plate is designed with a sharp edge to ensure predictable flow separation and accurate measurement.

Flow Conditions

The Reynolds number, which indicates whether flow is laminar or turbulent, also affects pressure drop. At higher Reynolds numbers, turbulence downstream is greater, and losses increase. At lower Reynolds numbers, flow may remain more stable, and pressure recovery may be higher.

Compressibility of the fluid is another factor. For gases, changes in density as the fluid accelerates through the orifice influence the pressure profile. For liquids, the effect is less complex, but cavitation can occur if the pressure at the vena contracta drops too low. This condition not only increases pressure drop but also risks damaging the plate and piping.

System Design Considerations

The placement of the orifice plate within a piping system also influences the pressure drop. If the flow is not fully developed upstream, additional turbulence may form at the plate. Proper straight pipe lengths before and after the orifice plate are required to reduce these effects.

Engineers must balance the accuracy of measurement against the energy cost of pressure loss. In large systems, the cumulative effect of pressure drops across multiple flow meters can significantly increase pumping requirements.

Comparisons with Other Flow Meters

Venturi Meters

Compared to the orifice plate flow meter, the venturi meter produces a smaller permanent pressure drop. This is because the venturi meter uses a smoothly tapered design that minimizes turbulence. However, venturi meters are more expensive and larger in size. The orifice plate, despite its greater losses, remains popular due to its simplicity and low cost.

Flow Nozzles

Flow nozzles represent a middle ground. They have higher recovery than orifice plates but less than venturi meters. The choice among these devices depends on the importance of energy efficiency, cost, and space constraints.

Practical Implications of Pressure Drop

Energy Costs

Permanent pressure loss in an orifice plate flow meter means that pumps or compressors must work harder to maintain desired flow rates. In systems where energy costs are critical, this loss becomes an important design factor. Engineers must calculate whether the simplicity of the orifice plate justifies the increased energy demand.

Measurement Accuracy and System Life

The pressure drop also relates to accuracy. A larger pressure differential makes it easier to measure flow precisely. However, excessive drops may strain equipment and reduce efficiency. Careful selection of the orifice size ensures that accuracy is achieved without excessive energy loss.

Conclusion

The orifice plate flow meter operates on a simple principle: a restriction in the pipe creates a pressure difference that can be measured to determine flow rate. Yet this principle inherently leads to pressure drop. As the fluid accelerates through the orifice and contracts at the vena contracta, pressure falls. While some recovery occurs downstream, turbulence ensures that a permanent loss remains.

This pressure drop is influenced by orifice geometry, flow conditions, and system design. Although the orifice plate is less efficient than venturi meters or flow nozzles, its low cost and reliability make it a preferred choice in many applications. Engineers must weigh the benefits of accuracy and simplicity against the energy losses caused by pressure drop.

Understanding how pressure drop occurs in an orifice plate flow meter system helps ensure that these devices are used effectively. It shows that measurement always comes with a cost, but with careful design, the balance between efficiency and accuracy can be achieved.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness