Are diaphragm pressure gauges good for sanitary applications?

Diaphragm pressure gauges are widely used in industries where measuring pressure accurately is crucial. These devices use a flexible diaphragm to sense pressure changes in liquids or gases. The movement of the diaphragm is converted into a mechanical reading on a gauge. This design makes diaphragm pressure gauges versatile and reliable.

In sanitary applications, such as food, beverage, pharmaceutical, and biotechnology processes, equipment must meet strict hygiene standards. Any contamination can compromise product quality and safety. Therefore, selecting pressure measurement devices that meet sanitary requirements is critical.

This article examines whether diaphragm pressure gauges are suitable for sanitary applications. It discusses their design, advantages, limitations, and best practices for installation and maintenance.

Understanding Diaphragm Pressure Gauges

Principle of Operation

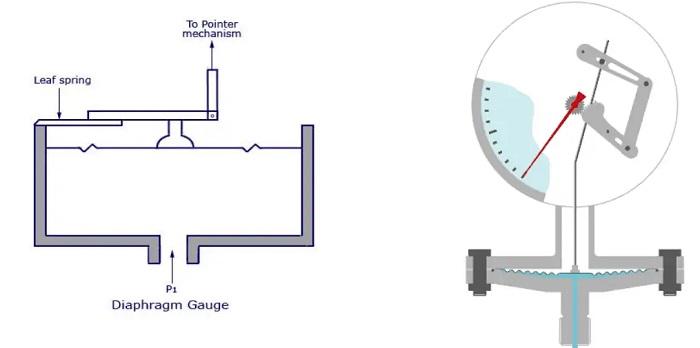

Diaphragm pressure gauges measure pressure by detecting the deflection of a flexible diaphragm. When pressure is applied to the diaphragm, it bends slightly. This bending moves a mechanical linkage that drives a pointer on a calibrated dial.

The gauge may be designed with a metallic or elastomer diaphragm. Metallic diaphragms provide high accuracy and resistance to high temperatures and corrosive fluids. Elastomer diaphragms are more flexible and can handle low-pressure ranges. Both designs isolate the process fluid from the mechanical components, which is especially important in sanitary applications.

Isolation of Process Media

One of the key features of diaphragm pressure gauges is the isolation of process media. The diaphragm prevents the fluid from contacting the internal components of the gauge. This prevents contamination and protects the gauge from corrosive or viscous fluids. In sanitary applications, this isolation ensures that the fluid remains uncontaminated and that the gauge remains functional for extended periods.

Advantages in Sanitary Applications

Hygienic Design

Diaphragm pressure gauges can be designed to meet sanitary standards. They often include smooth surfaces, polished diaphragms, and connections compatible with tri-clamp or other sanitary fittings. Smooth surfaces reduce areas where bacteria or product residue can accumulate, making cleaning and sterilization easier.

The ability to use common sanitary connections simplifies integration into existing pipelines. Many diaphragm pressure gauges are compatible with CIP (clean-in-place) and SIP (sterilization-in-place) procedures, which are standard in food and pharmaceutical industries.

Accuracy and Sensitivity

Diaphragm pressure gauges provide accurate readings even at low pressures. Their sensitivity makes them suitable for processes where small pressure changes can affect product quality. Accurate monitoring helps maintain consistent process conditions, which is critical in sanitary applications.

Durability and Reliability

The isolation provided by the diaphragm protects the gauge from harsh fluids. This reduces maintenance needs and extends the life of the device. In sanitary processes, where downtime can be costly, durability is a significant advantage.

Compatibility with Corrosive Fluids

Many sanitary applications involve fluids that are acidic or alkaline. Diaphragm pressure gauges with stainless steel or Hastelloy diaphragms resist corrosion. This ensures reliable operation while maintaining sanitary standards.

Limitations and Considerations

Pressure Range Limitations

While diaphragm pressure gauges are accurate at low to moderate pressures, they may be limited at very high pressures. Users must select gauges designed to handle the expected process pressure to avoid damage or inaccurate readings.

Temperature Sensitivity

Extreme temperatures can affect the diaphragm material. Elastomer diaphragms may degrade under high heat, while metallic diaphragms can expand slightly, affecting accuracy. For sanitary applications involving steam or hot fluids, choosing a diaphragm material compatible with the temperature range is essential.

Mechanical Wear

Although the diaphragm isolates the gauge from the fluid, mechanical linkages inside the gauge are still subject to wear. Frequent calibration and maintenance may be needed to ensure continued accuracy, especially in continuous process environments.

Cleanability and Design Complexity

Not all diaphragm pressure gauges are equally easy to clean. Gauges with complex housings or hard-to-reach areas can trap residue. In sanitary applications, devices must be chosen for their cleanable design and compatibility with sterilization procedures.

Best Practices for Sanitary Installation

Proper Fittings

Using sanitary fittings such as tri-clamps or threaded connections ensures a leak-free installation. This prevents contamination and allows the gauge to be easily removed for cleaning or maintenance.

Orientation and Placement

Diaphragm pressure gauges should be installed in a position that allows proper drainage and avoids fluid accumulation on the diaphragm. Horizontal or vertical mounting depends on process requirements, but proper placement ensures consistent readings and easier cleaning.

Regular Maintenance

Even in sanitary conditions, diaphragms can wear over time. Regular inspection and calibration ensure that the gauge remains accurate. Using spare diaphragms or easily replaceable modules reduces downtime in critical processes.

Cleaning Procedures

Compatibility with CIP and SIP procedures is essential. Before selecting a diaphragm pressure gauge, verify that it can withstand the chemicals, temperatures, and pressures used in cleaning and sterilization processes. Polished diaphragms and smooth housing surfaces facilitate proper cleaning.

Case Studies in Sanitary Applications

Food and Beverage Industry

In beverage production, diaphragm pressure gauges monitor carbonation levels and liquid flow. Hygienic design prevents bacterial growth and ensures accurate control of pressure during filling processes. Stainless steel diaphragms resist corrosion from acidic liquids like fruit juices.

Pharmaceutical Industry

In pharmaceutical processes, precise pressure monitoring is crucial for filtration and transfer of sterile fluids. Diaphragm pressure gauges prevent contamination while maintaining accuracy. CIP and SIP procedures ensure that the gauges do not introduce pathogens into sterile production lines.

Biotechnology Applications

Bioreactors and fermentation systems require careful control of gas and liquid pressures. Diaphragm pressure gauges provide the sensitivity and sanitary design needed to maintain controlled environments. Smooth surfaces and chemical resistance are essential for maintaining sterile conditions.

Conclusion

Diaphragm pressure gauges are generally well-suited for sanitary applications. Their ability to isolate the process fluid, combined with accurate pressure measurement, makes them reliable and safe for industries such as food, beverage, pharmaceutical, and biotechnology.

Proper selection of diaphragm material, gauge design, and sanitary fittings is critical. Attention to installation, orientation, and regular maintenance ensures optimal performance. While they have limitations in very high-pressure or extreme-temperature conditions, modern designs overcome many of these challenges.

In conclusion, diaphragm pressure gauges are effective and practical for sanitary applications. Their hygienic design, durability, and accuracy make them a preferred choice where maintaining fluid purity and precise pressure measurement are essential.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness